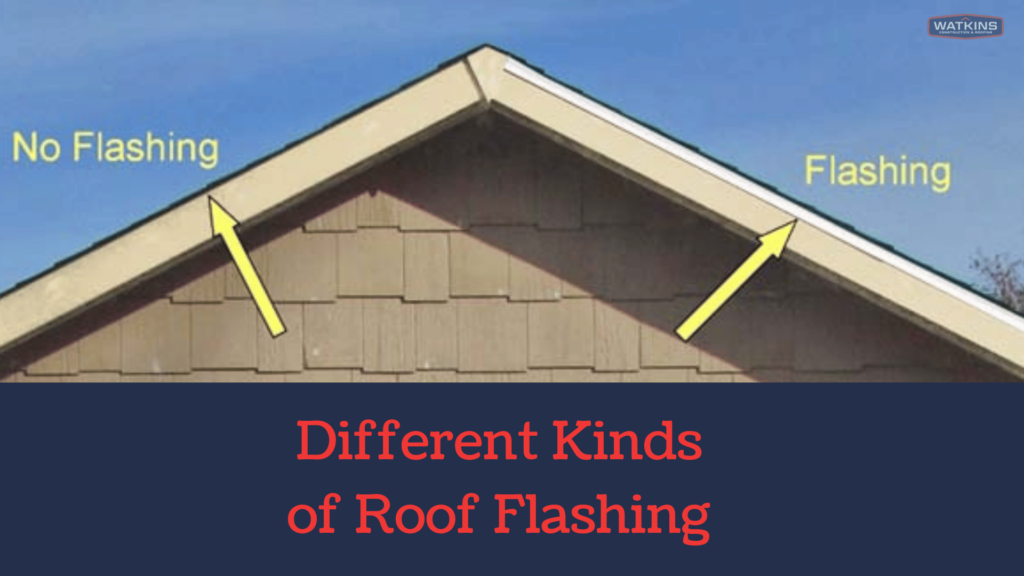

Watkins Construction & Roofing has provided you an article on the different kinds of roof flashing. Your shingles may be in good condition, but there are still many entry points for water in a roof. Here is where roof flashing earns vital importance.

Flashing seal the roof’s joints with other surfaces, such as the chimney, vents, walls, and eaves. Every roof requires proper flashing because of the high volume of water that might flow through their valleys.

Different kinds of flashing exist. Some only apply conditions. Thus, it is necessary to know the different types of flashing available, given the critical function of this material.

- Counter Flashing

Flashing’s aim is to divert water away from the joints between the roof and the brick or masonry walls. Chimneys typically have counter flashing installed around them.

Counter flashing is most effective when set in the mortar joints. Roofers can also ground existing mortar joints down to install counter flashing. Then, they seal them with solder and brickwork.

- Flashing Steps

Where the roof meets a vertical wall or chimney, contractors use step flashing to divert water away from the joint.

They put a rectangular piece of metal in the joint to prevent roof leaks.

Typically, step flashing is made of aluminum or galvanized steel because of its durability and resistance to corrosion.

- Apron Flashing

Apron flashing, also called headwall flashing, is installed along the upper edge of a roof that ends in a vertical headwall. This L-shaped metal flashing is available in lengthy lengths, allowing a smooth transition in these critical places.

- Gutter Apron Flashing

Where the gutter joins the roof, there is typically a space. Long sections of gutter apron flashing are bent to direct water into the gutters. It shields the fascia and other vulnerable components under the eaves from rain and snow.

- Drip Edge Flashing

Drip edges need flashing too. However, instead of an L-shape, it has a T-shaped cross-section. It keeps the fascia dry and prevents water from pooling up around it.

You might need to inquire about drip edge flashing when installing a new roof. It is rarely part of a typical roof installation.

- Penetration Flashing

Your roof’s vents have exposed seams that you must flash to prevent water damage. Collars, sleeves, and membranes are used in this sort of flashing to seal off the area surrounding a vent and keep water out.

- Ridge/Hip Flashing

To prevent water damage to the building, you must install flashing at the crest where two roof planes meet. Also, you can include architectural details, such as rounded ridge caps, into ridge and hip flashings to give your roof a polished aesthetic. Copper is only one of several color and material options for these flashings.

- Valley Flashing

Valley flashing is essential to the safety of water collection and distribution lines. Roofers can install valley flashing on a roof in different ways using diverse materials. At the foot of a steep decline, two v-shaped valleys converge. A piece of flashing in the shape of a “w” has a ridge that rises in the middle. With the ridge in place, the rain will not flow under the tiles on the next roof.

Open valley flashing is more long-lasting than its closed counterpart. However, the setup procedure is more complex and costly.

- Cap Metal Flashing

Waterproofing a parapet’s cap requires the application of cap metal flashing. The parapet will be securer by installing a waterproof membrane behind the flashing. Unlike residential roofs, business buildings frequently use cap metal flashing.

- Gravel Stops

This kind of flashing serves several purposes. On a concrete roof, it has a raised edge that traps gravel and other debris. It has a drip edge that channels rainwater into the gutters. Gravel stops shield the fascia, and completes the look of concrete roofs.

- Door and Window Flashing

Proper flashing around doors and windows is necessary to keep water out. A wide selection of flashings is available for use around windows and doors. Drip-cap and self-adhesive flashing are two common choices.

Using Flashing Properly

Flashing, when installed correctly, prevents water from seeping into the roof decking and skeleton, which, in turn, protects the entire house. However, roofing contractors must place it with a substantial exterior material overlap to provide a leak-proof seal.

Flashing is often silver, but it is available in several colors.

You should also apply an ice and water shield with the flashing installation. This element strengthens the waterproofing of particular spots. However, using ice and water shields excessively might obstruct the airflow on your roof. Because of this, hiring a professional contractor is crucial for flashing installation and maintenance.

For more information, you can reach Watkins Construction & Roofing at 601-488-3179. We service areas in Jackson, Flowood, Clinton, and Ridgeland, MS.